Mechanical Vices at partsformachines.com: A Comprehensive Guide on how to select the best Vice suited to your needs

Introduction: Vices are renowned for their exceptional quality, durability, and precision. These vices are essential tools for professionals in various industries, including automotive, manufacturing, and construction. In this comprehensive guide, we will explore the features and benefits of Vices and provide you with a step-by-step selection process to help you find the perfect vice for your needs.

Understanding Vices:

Understanding Vices:

Over many years,

SIP,

Sealey,

Draper and

Sykes Pickavant have been leading manufacturer of high-quality tools and equipment. Their vices are known for their robust construction, innovative design, and outstanding performance. Sykes Vices are engineered to withstand heavy-duty use and provide a secure grip for a wide range of applications. These vices are favoured by professionals for their reliability, precision, and durability.

At partsformachines.com the Vices we sell are constructed from top-grade materials such as hardened steel, they can withstand rigorous use and resist wear and tear. This durability ensures that the vice remains in excellent working condition for years to come.

The precision engineering of Vices guarantees accurate and consistent results. Our vices feature smooth operation and fine adjustment options, allowing for precise positioning and alignment of the workpiece. This level of control is crucial for achieving high-quality output.

How to select a Vice:

To ensure you choose the most suitable Vice for your specific requirements, follow these step-by-step selection guidelines:

Step 1

Step 1:

Assess Your Needs: Identify the tasks you regularly perform and determine the maximum size and weight of the workpieces you work with. Understanding your needs will help you select a vice that can handle your workload efficiently.

Step 2:

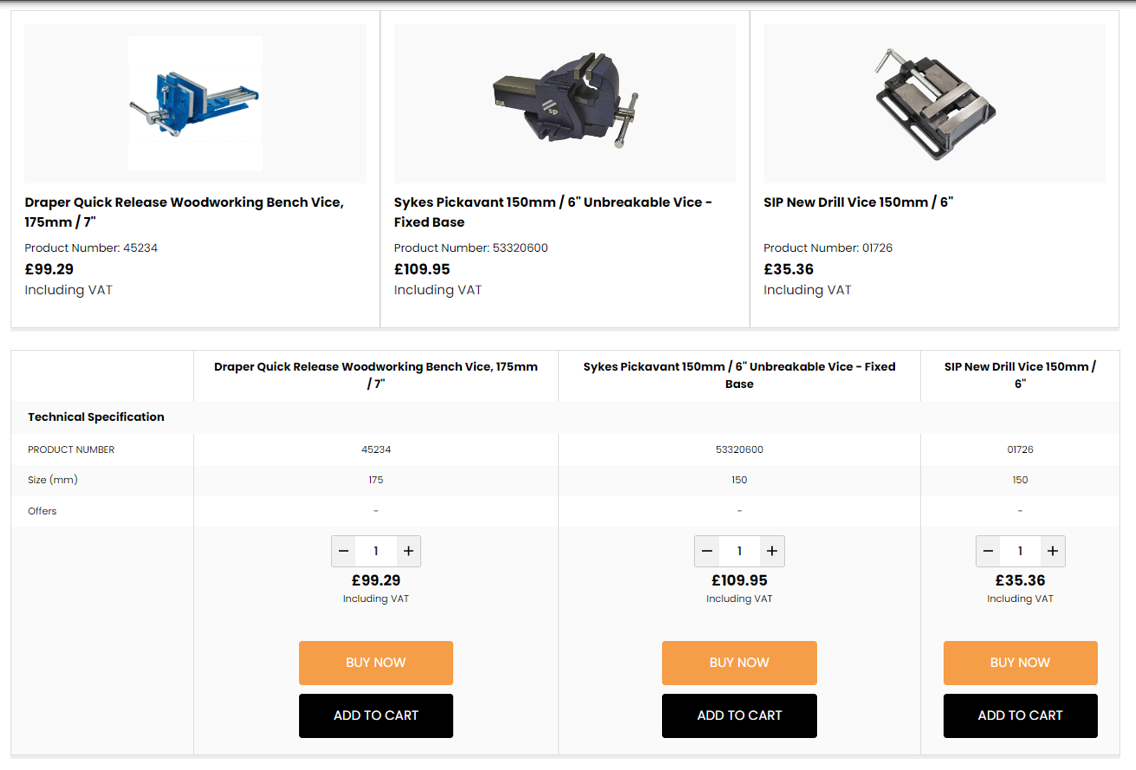

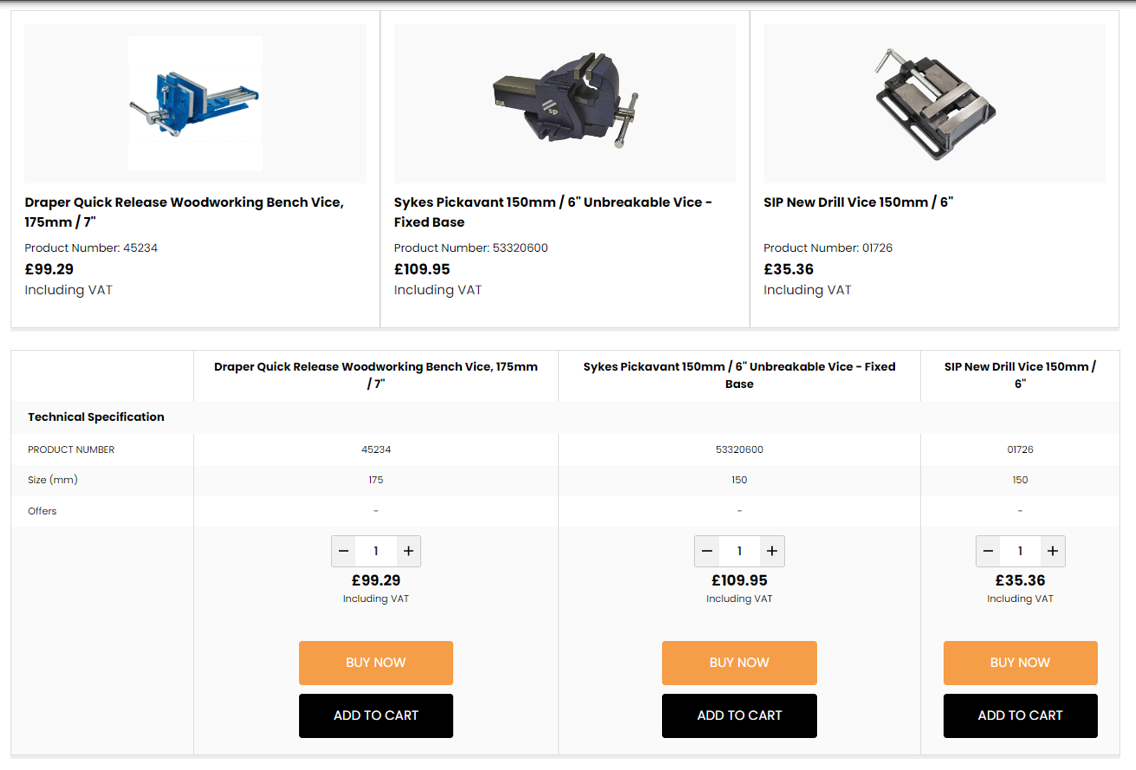

Determine Vice Type: SIP, Sealey, Draper and Sykes Pickavant offers a variety of vice types, including

bench vices,

fixed base vices,

engineer's vices, and

drill press vices. Consider the nature of your work and the workspace available to you. Choose a vice type that suits your specific needs.

Step 3: Evaluate Jaw Size and Capacity: Check the maximum opening width and depth of the vice jaws. Ensure that they can comfortably accommodate your typical workpieces. Having sufficient jaw size and capacity is crucial for securely gripping and manipulating various materials.

Step 4: Consider Mounting Options: Determine whether you require a vice that can be permanently mounted to a workbench or a portable one that can be easily attached and detached. Consider your workspace limitations and mobility needs when selecting the mounting style.

Step 5: Additional Features: Vices come with various additional features, such as swivel bases, anvil surfaces, and pipe jaws. Assess which features are essential for your specific tasks. For example, a swivel base offers increased maneuverability, while pipe jaws are ideal for working with cylindrical objects.

----------------------Conclusion----------------------

Partsformachines.com offers high quality Vices that are trusted by professionals worldwide for their outstanding quality, precision, and durability. By following the step-by-step selection process outlined in this guide, you can confidently choose the perfect vice for your specific needs. Whether you're working with automotive components, metalwork, or general assembly.

Understanding Vices:

Understanding Vices: Step 1: Assess Your Needs: Identify the tasks you regularly perform and determine the maximum size and weight of the workpieces you work with. Understanding your needs will help you select a vice that can handle your workload efficiently.

Step 1: Assess Your Needs: Identify the tasks you regularly perform and determine the maximum size and weight of the workpieces you work with. Understanding your needs will help you select a vice that can handle your workload efficiently.