Quick delivery and the product at a very competitive price.

Highly Recommend

I ordered a starter motor for my Polaris ranger, best price around and prompt service.

thanks for sending the part so quickly, and was just the job

1st class,excellent service.

Excellent service

You stock the parts that I needed and delivered quickly and efficiently.

Worth the Money

Strong and Excellent Quality.

10 out of 10 from me!

Great price.

Great delivery.

Very easy transaction the machine arrived on time and well packaged,

Absolutely spot on!

Excellent website, easy ordering, great price, speedy delivery and an excellent machine at an excellent price!

Thanks very much!!

Great service with speedy delivery, easy ordering system and great during & after service support.

Rating

Rating

Standard Delivery: £30.99

Standard Delivery: £30.99

Delivery Estimate: 2 to 3 working days

Delivery Estimate: 2 to 3 working days

Save Extra With 1 Offer

Save Extra With 1 Offer

Compare With Similar Items

Compare With Similar Items

A. Standard UK delivery is 3–5 working days.

A. No, delivery charges are calculated separately at checkout based on order weight, size, and delivery location.

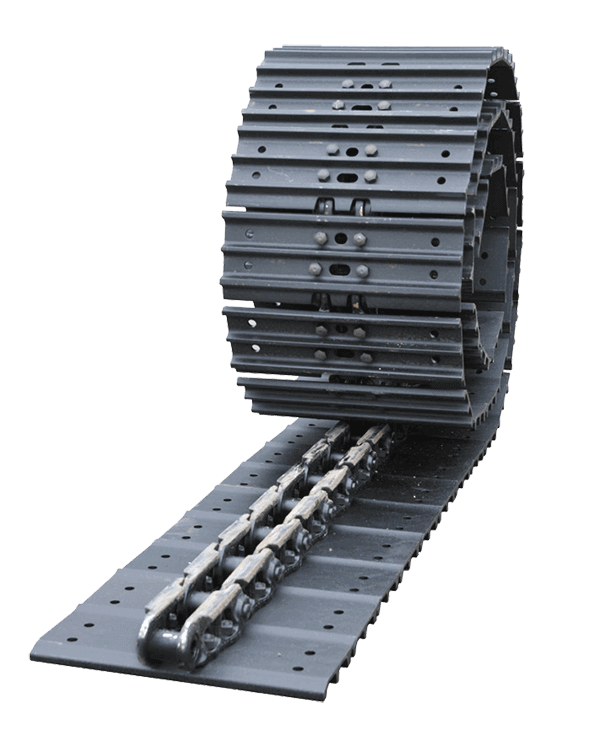

A. We’ve prepared a detailed guide on our Blogs & Insights Tab which explains step-by-step how to select the correct tracks and other undercarriage parts.

Finding the Perfect Fit: How to Identify the Correct Track Size

A. Steel tracks are measured by shoe width (mm), pitch (distance between pin centers), and number of links. For example, a 600mm shoe width × 175mm pitch × 49 links.

A. Sealed Chains: Grease-sealed pins to prevent dirt ingress, common in general applications.

Lubricated Chains: Oil-lubricated pins for reduced friction, longer life in high-hour or abrasive use.

A. Wider shoes: Lower ground pressure, better flotation in soft ground, but more stress on links.

Narrower shoes: Better traction in rocky/firm ground, less stress on the chain.

A. Steel tracks can last thousands of operating hours depend on ground conditions, shoe type, and maintenance. Operating on rock or abrasive ground reduces lifespan significantly.

A. Pins, bushings, and shoes wear fastest. Excessive “pitch elongation” (stretched chain length) is a key sign the track is at end-of-life.

A. Steel tracks are ideal for rocky, uneven, and abrasive terrains where durability and strength are critical. They are less suitable for paved surfaces, as they may cause surface damage.

A. Steel tracks are designed for tough, abrasive environments like demolition, quarrying, and mining. They provide superior durability, higher load-bearing capacity, and better traction on rocky or uneven terrain.

A. Yes. Steel track assemblies come as a complete unit with linked shoes ready to be fitted, ensuring proper performance and easy installation.

By sharing your email, you agree to our privacy policy & terms of service