Quick delivery and the product at a very competitive price.

Highly Recommend

I ordered a starter motor for my Polaris ranger, best price around and prompt service.

thanks for sending the part so quickly, and was just the job

1st class,excellent service.

Excellent service

You stock the parts that I needed and delivered quickly and efficiently.

Worth the Money

Strong and Excellent Quality.

10 out of 10 from me!

Great price.

Great delivery.

Very easy transaction the machine arrived on time and well packaged,

Absolutely spot on!

Excellent website, easy ordering, great price, speedy delivery and an excellent machine at an excellent price!

Thanks very much!!

Great service with speedy delivery, easy ordering system and great during & after service support.

Standard Delivery: £4.99

Standard Delivery: £4.99

Delivery Estimate: 2 to 4 working days

Delivery Estimate: 2 to 4 working days

Save Extra With 1 Offer

Save Extra With 1 Offer

Compare With Similar Items

Compare With Similar Items

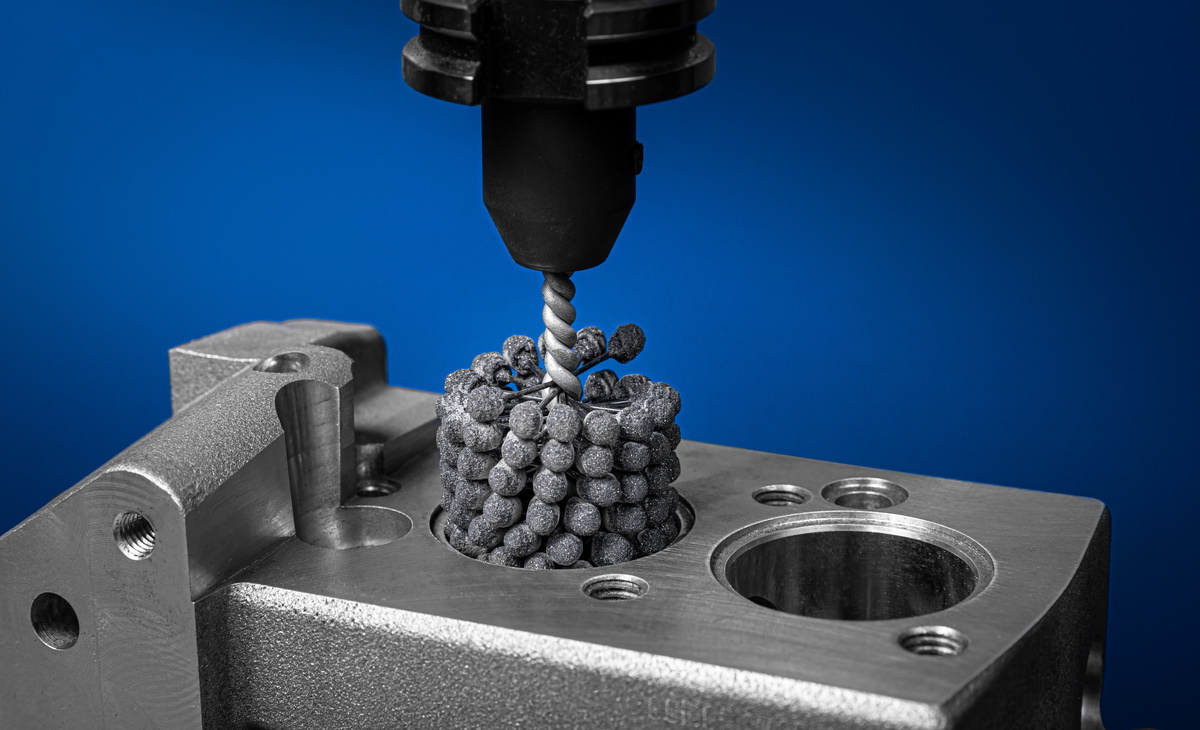

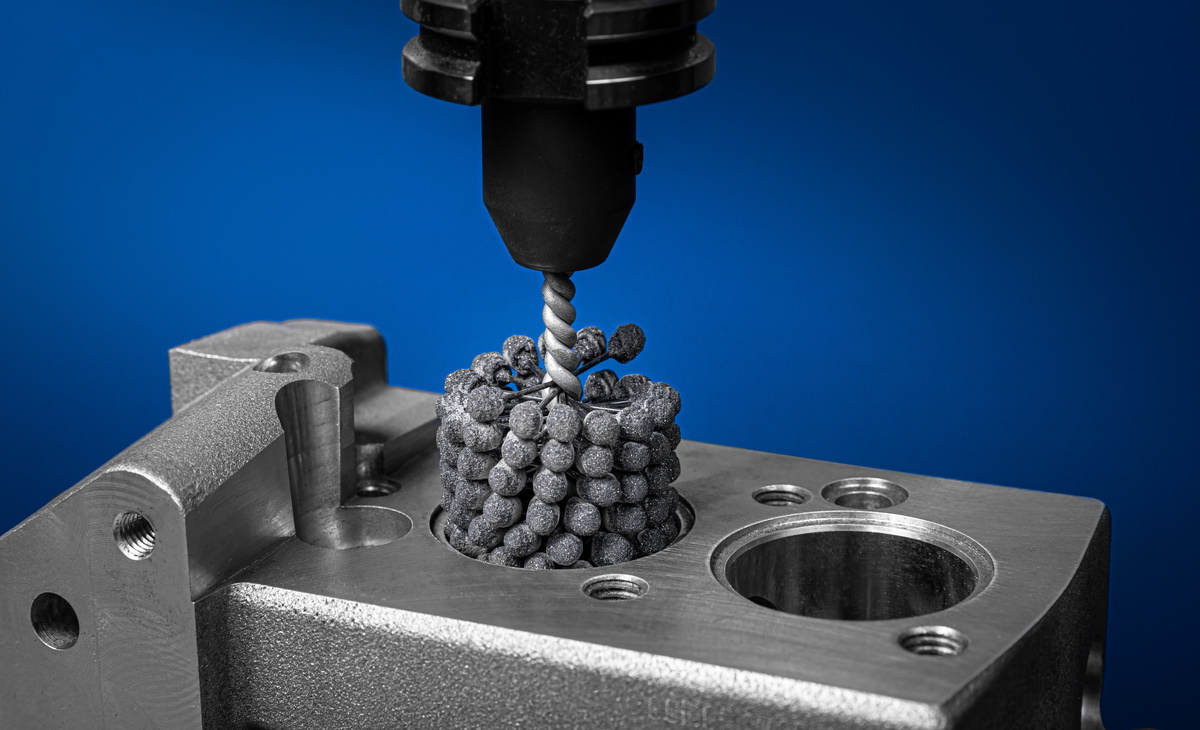

A. They are designed for:

Internal surface finishing

Deburring, polishing, and honing cylindrical bores or tubes

Cleaning and preparing surfaces for coating or welding

Removing rust, scale, or residue from valve seats, bushings, or pipes

A. Abrasive nylon filament embedded with SiC (Silicon Carbide) grit

Grit types: 120 or 180 (depending on aggressiveness required)

Stainless steel wire shank

A. Yes, most come with a 3mm–7mm shaft designed for:

Hand drills

Flexible shafts

CNC machining centers (if RPM range is within limit)

Always check the recommended maximum RPM.

A. Use these selection points:

Requirement : Brush Feature

Light polishing : Grit 180

Aggressive deburring : Grit 120

Bore size match : Choose a brush with diameter range slightly under the bore ID

Deep or long bore : Opt for longer bristle and shaft (200mm here)

A. Yes, but:

Use higher grit (180) for soft materials

Avoid high pressure or RPM that could overheat or gouge surfaces

A. Automotive & aerospace workshops

Hydraulic and pneumatic component maintenance

Metal fabrication & machining

Tool and die shops

Valve and cylinder manufacturers

A. Grit 120: Coarser, removes more material faster

Grit 180: Finer, produces a smoother surface finish

A. The brush is optimized for bores or holes within that diameter range. It ensures effective brushing without excessive wear or insufficient contact.

A. Generally, between 600–1,200 RPM is ideal

Do not exceed 2,500 RPM to prevent overheating or filament damage

By sharing your email, you agree to our privacy policy & terms of service